AUMAT Maschinenbau GmbH

Kyllmannweg 19

42699 Solingen

info@aumat.de

Telefon

0049 (0) 212 / 38 245 - 0

Patented process - cycle time 5.5 sec. With this installation AUMAT proudly presents a patented solution for the milling of longitudinal profiles for variable key-lock systems. This patented milling process achieves the aim that -in spite of the large number of variants - only a limited number of shank cutters is used.

This results in numerous advantages:

Thus does the patented milling process function:

The (same) milling stations are arranged - in the required number - for the first shaft end of the key (e.g. as 3 or 4) peripheral to a precision rotary table, and in the same way for the second shaft end.

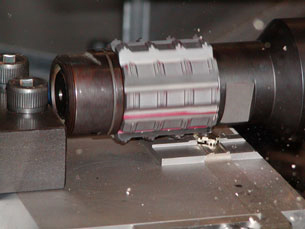

Each station has only a single router. This router usually has 4 milling segments set in the axial direction, of which per milling operation (via postponed control) only one milling segment comes into action.

In this way each station carries two variants of the shaft, such as A and B according to the rule "with A / with B - no A / no B - with A / no B - without B / no A"